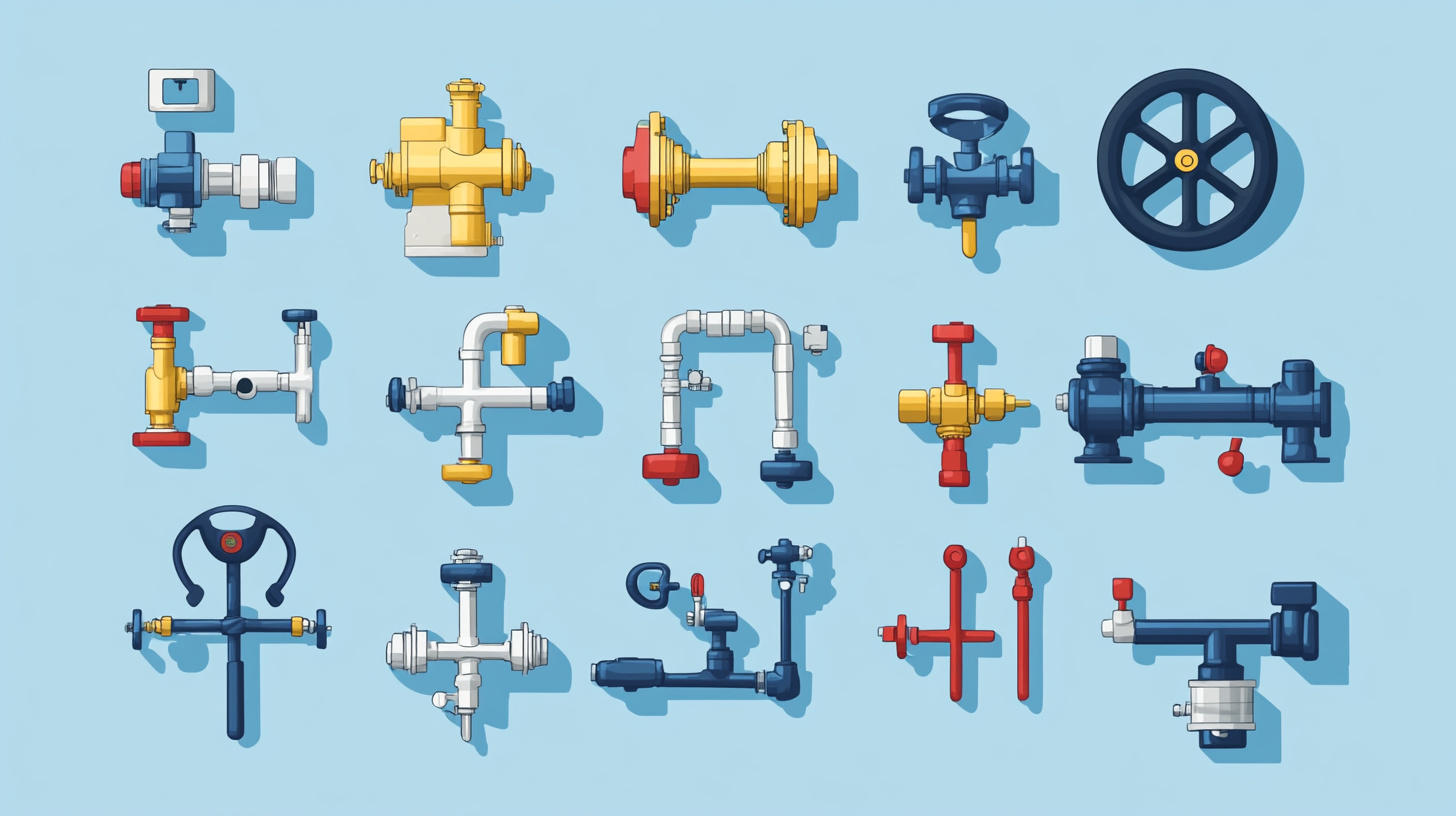

Types of Valves – A Comprehensive Guide

Valves may appear to be small parts in a larger system, but their significance is far from minor. Whether you’re a plumber handling residential plumbing, a contractor managing industrial systems, or a DIY enthusiast working on a home project, selecting the right valve is essential for maximizing efficiency and ensuring safety.

This guide will take you through the different types of valves, their uses, and provide key tips on selection and maintenance to help you make well-informed decisions.

What is a Valve?

Definition and Function

A valve is a device used to control or regulate the flow of fluids or gases by opening, closing, or partially blocking the pathway. Valves are essential components in systems ranging from everyday plumbing to complex industrial processes, such as oil and gas operations.

Key Valve Components

Understanding a valve’s anatomy can help you choose the right one for your needs. Most valves consist of:

- Body: The outer casing.

- Stem: Connects the actuator to the valve mechanism.

- Seat: Seals the valve and stops leakage.

- Disc: The mechanism that regulates flow.

- Actuator: Manages the opening and closing of the valve.

How Valves Work

Valves can open or close fully for on/off control or modulate to allow variable flow rates, depending on the application. Their operation can be manual or automated using actuators.

Common Types of Valves

1. Ball Valves

- Description: A ball with a hole in the center controls the flow by rotating the ball.

- Applications: Ideal for plumbing, gas pipelines, and industrial use.

- Advantages: Durable, reliable, and easy to operate.

2. Gate Valves

- Description: Operates by lifting a gate to permit or block flow.

- Applications: Used in main water supplies, oil pipelines, and treatment plants.

- Advantages: Creates minimal pressure drop and allows full flow.

3. Globe Valves

- Description: Features a disc that regulates flow rate, perfect for throttling.

- Applications: Steam systems, HVAC, and heating systems.

- Advantages: Accurate flow regulation.

4. Check Valves

- Description: Ensures the fluid flows in one direction, preventing backflow.

- Applications: Water pumps, wastewater systems.

- Advantages: Prevents contamination and damage from reverse flow.

5. Pressure Relief Valves

- Description: Automatically releases excessive pressure.

- Applications: Boilers and gas systems.

- Advantages: Safeguards systems from over-pressurization.

6. Butterfly Valves

- Description: Rotates a disc to control flow.

- Applications: Large pipelines, HVAC systems.

- Advantages: Compact, lightweight, and cost-efficient.

7. Ball Check Valves

- Description: Uses a ball to prevent reverse flow.

- Applications: Pumps and industrial processes.

- Advantages: Reliable and simple.

8. Needle Valves

- Description: Uses a tapered needle for precise flow control.

- Applications: Laboratory setups, precision systems.

- Advantages: Excellent for controlling small flow rates.

9. Solenoid Valves

- Description: Electrically controlled for automation.

- Applications: HVAC, irrigation systems, automation.

- Advantages: Offers remote and precise control.

Valve Materials

Common Materials

The material plays a crucial role in how well a valve performs. Common options include:

- Brass (durable, for residential use)

- Stainless Steel (corrosion-resistant)

- Cast Iron (cost-effective for industrial systems)

- PVC (lightweight and chemical-resistant)

Choosing the Right Material

Consider factors like corrosion resistance, system temperature, and fluid pressure to select the most suitable material.

How to Choose the Right Valve

The right valve ensures safe and efficient operation. Here’s what to consider:

- Fluid or Gas Type: Ensure compatibility with the valve material.

- Flow Control Needs: Evaluate if you need on/off or modulating control.

- Pressure and Temperature Ratings: Match the valve’s specifications to your system.

- Valve Size: Ensure compatibility with your pipe diameter.

- Application Environment: Choose appropriate valves for residential, commercial, or industrial settings.

Valve Actuators

Types of Actuators

- Manual Actuators: Handwheels and levers for simple manual control.

- Electric Actuators: Ideal for automation.

- Pneumatic Actuators: Powered by compressed air, great for precise control.

- Hydraulic Actuators: Use fluid pressure for robust applications.

Choosing a suitable actuator depends on your system’s level of automation and operation requirements.

Valve Installation & Maintenance

Installation Tips

- Always align the valve correctly with the system.

- Use sealants to prevent leaks.

- Test the valve after installation to ensure proper function.

Maintenance Practices

- Perform regular inspections for wear.

- Lubricate moving parts to prevent seizing.

- Clean debris from valves to avoid clogging.

Industry-Specific Valve Applications

- Residential Plumbing: Valves used to control water or gas supply.

- Industrial Applications: Valves for handling chemicals, gases, and oils.

- HVAC Systems: Valves in ventilation, cooling, and heating systems.

- Agricultural Systems: Used in irrigation systems for precise water flow.

- Automotive: Critical for engine fuel systems and braking.

Emerging Trends in Valve Technology

- Smart Valves: IoT-enabled valves for real-time monitoring and remote control.

- Eco-Friendly Valves: Focused on sustainability with lower energy usage and eco-friendly materials.

- Advanced Coatings: Innovative coatings for better corrosion resistance.

Master Your Valve Choices for System Efficiency

Selecting the right valve requires understanding the fluid, pressure, and application environment. A poor choice can lead to inefficiency, leaks, and even costly system failures. By following this guide, you’ll be better equipped to make informed decisions for your projects.

Whether you’re a plumber addressing residential concerns or a contractor managing an industrial system, choosing the right valve improves performance and ensures long-term safety. Visit our homepage or contact us to explore more valve solutions or get expert advice tailored to your needs.